Introduction

Fuel management has become increasingly important for businesses that rely on vehicles, heavy machinery, and fuel-powered equipment. Rising fuel prices, operational inefficiencies, and fuel theft have made traditional fuel monitoring methods unreliable and costly. Manual tracking systems often lead to inaccurate data, unauthorized fuel usage, and lack of operational visibility.

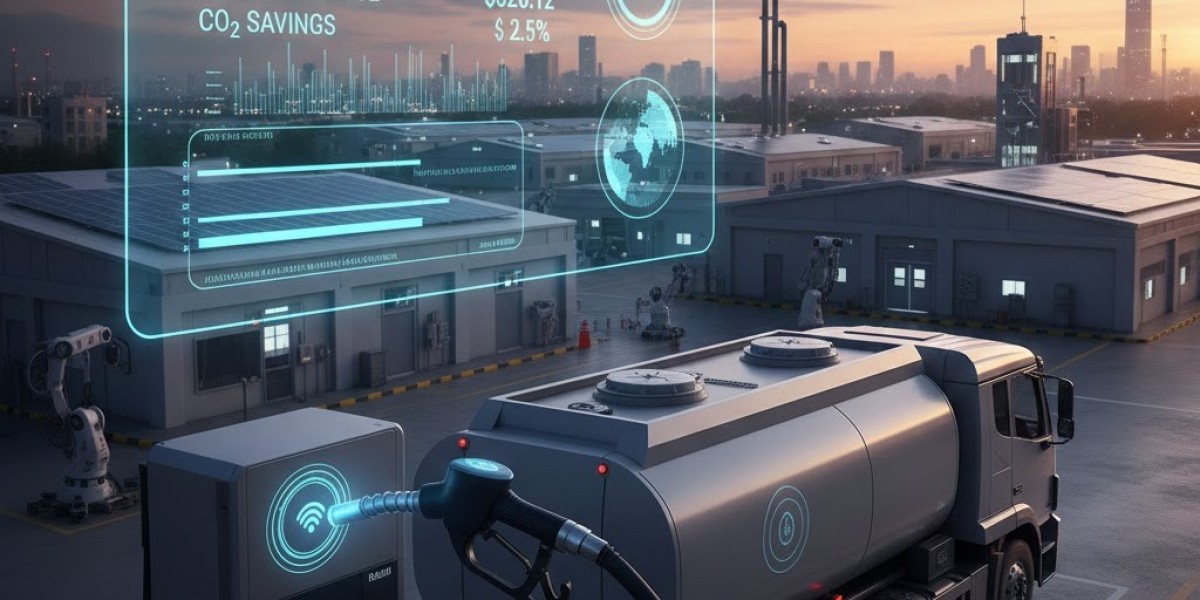

This is why many organizations are adopting RFID fuel management systems. These advanced solutions use radio frequency identification technology to automate fuel tracking, control fuel dispensing, and provide real-time operational insights. By integrating RFID tags, smart fuel dispensers, and cloud-based monitoring platforms, businesses can achieve higher efficiency and better cost control.

In this article, we will explore how RFID fuel management systems work, their key components, benefits, and how they are transforming modern fuel operations.

What Are RFID Fuel Management Systems?

RFID fuel management systems are automated fuel monitoring platforms that use RFID technology to identify vehicles, drivers, or equipment during the fueling process. Each asset is assigned a unique RFID tag that communicates with RFID readers installed at fueling stations.

When a tagged vehicle arrives for refueling, the RFID reader verifies authorization before allowing fuel dispensing. The system records all fueling data automatically, including:

Asset identification

Fuel quantity dispensed

Fueling location

Date and time of fueling

Operator information

This automated process eliminates manual errors and ensures accurate fuel tracking across operations.

How RFID Fuel Management Systems Work

RFID Tagging and Identification

Each vehicle or piece of equipment is equipped with a unique RFID tag that stores identification details. These tags are durable and designed for long-term use.

RFID Readers at Fuel Dispensers

Fuel pumps are equipped with RFID readers that scan tags and communicate with the control system to verify authorization.

Automated Fuel Dispensing Process

Once authorization is confirmed, fuel is dispensed automatically. If the asset is not authorized, the system blocks fuel access.

Centralized Data Management

All fueling transactions are stored in a central database and can be accessed through web-based dashboards or mobile applications.

Monitoring and Alerts

Real-time alerts notify operators about unauthorized fueling attempts, abnormal fuel consumption, or system irregularities.

Key Features of RFID Fuel Management Systems

Real-Time Fuel Monitoring

Track fuel usage instantly across multiple vehicles, locations, and equipment.

Access Control and Authorization

Prevent unauthorized fueling by allowing only approved assets to receive fuel.

Automated Reporting and Analytics

Generate detailed reports on fuel consumption, operational trends, and performance metrics.

Integration with Fleet Telematics

RFID fuel management systems can integrate with GPS tracking and telematics solutions to provide complete operational insights.

Cloud-Based Dashboards

Access fuel data remotely through secure cloud platforms, enabling real-time monitoring from anywhere.

Benefits of Implementing RFID Fuel Management Systems

Reduction in Fuel Theft

Automated authorization ensures that only approved vehicles can access fuel, reducing unauthorized usage.

Improved Operational Efficiency

Automation eliminates manual data entry and reduces administrative workload.

Accurate Fuel Data

Real-time monitoring provides precise and reliable fuel consumption information.

Enhanced Cost Control

Detailed analytics help organizations identify inefficiencies and optimize fuel usage.

Better Accountability

Each fueling transaction is recorded with asset identification, improving operational transparency.

Industries Benefiting from RFID Fuel Management Systems

RFID fuel management systems are widely used across various sectors:

Logistics and transportation companies

Construction and heavy equipment operations

Agriculture and farming industries

Mining and industrial facilities

Public transportation fleets

Oil and gas operations

Any organization that relies on fuel-consuming assets can benefit from automated fuel tracking.

Challenges Solved by RFID Fuel Management Systems

Traditional fuel monitoring methods often face issues such as:

Inaccurate manual records

Fuel theft and unauthorized fueling

Lack of operational transparency

Difficulty tracking fuel efficiency

Administrative complexity

RFID systems address these problems by providing automated and accurate fuel monitoring.

Future Developments in RFID Fuel Management Systems

With advancements in digital technology, RFID fuel management systems are becoming more intelligent and efficient. Emerging innovations include:

IoT-enabled fuel monitoring sensors

Artificial intelligence for predictive fuel analytics

Mobile applications for remote monitoring

Integration with smart fleet management platforms

Automated maintenance and fuel efficiency alerts

These technologies will continue to improve operational efficiency and fuel management accuracy.

Best Practices for Successful Implementation

To maximize the benefits of RFID fuel management systems, organizations should:

Use high-quality RFID tags and readers

Train staff on automated fueling processes

Regularly analyze fuel consumption reports

Integrate systems with fleet management tools

Establish clear fuel authorization policies

Proper implementation ensures reliable performance and long-term operational improvements.

Conclusion

RFID fuel management systems are transforming how businesses monitor and control fuel usage. By automating fuel tracking and providing real-time data insights, these systems help organizations reduce fuel theft, improve operational efficiency, and make informed decisions.

As industries continue to embrace digital transformation, RFID-based fuel monitoring will become a standard practice for businesses seeking better cost control and operational transparency. Investing in advanced RFID fuel management systems today enables companies to achieve smarter fuel operations and long-term success.