Batteries are essential components in everyday life, powering devices from remote controls to high-tech electronics. However, due to their chemical composition, batteries are sensitive to environmental conditions and physical stress. Improper handling or packaging during storage and transport can lead to leakage, short-circuiting, or complete product failure.

A retail battery packaging solution plays a critical role in safeguarding batteries throughout the supply chain. From the manufacturer to the retailer, protective packaging ensures that batteries reach their destination intact, functional, and safe for consumers.

Why Secure Packaging Is Essential for Batteries

Batteries contain chemical compounds that can react adversely if exposed to moisture, heat, or mechanical stress. Secure packaging mitigates these risks by providing:

Physical protection against impacts, drops, or compression

Barriers to moisture and humidity

Insulation against short-circuiting caused by contact with metal objects

Clear labeling for handling and storage guidance

By addressing these concerns, battery packaging boxes not only preserve product integrity but also enhance consumer confidence in the brand.

Protecting Against Transport Hazards

During transportation, batteries are subject to various hazards, including vibration, shifting in transit, and temperature fluctuations. Poorly packaged batteries may experience:

Deformation or crushing

Leakage or chemical spills

Reduced performance due to thermal stress

Damage to neighboring products

A well-designed retail battery packaging solution ensures that batteries are securely contained, minimizing movement and protecting against external forces.

Safety-Compliant Packaging

Regulatory standards govern the safe packaging and shipping of batteries, particularly lithium-ion types. Safety-compliant battery packaging includes features such as:

Individual compartments for each battery to prevent short-circuits

Tamper-evident seals to ensure product integrity

Warning labels and handling instructions

Flame-retardant or reinforced materials for hazardous battery types

Meeting these standards protects both the product and the end-user while reducing liability for manufacturers and distributors.

Preserving Battery Longevity

Batteries are sensitive to environmental conditions, which can reduce their shelf life. Exposure to moisture, air, or heat can accelerate chemical degradation, leading to reduced performance or leakage. Protective packaging addresses these concerns through:

Airtight or moisture-resistant containers

Temperature-stable materials that insulate against heat or cold

Shock-absorbing designs to prevent impact damage

Using high-quality packaging ensures that batteries retain their energy capacity and functionality until they are used.

Eco-Friendly Packaging Options

With increasing awareness of environmental sustainability, many brands are shifting toward eco-friendly battery packaging. These options provide protection while reducing the environmental footprint. Features include:

Recyclable cardboard or molded pulp inserts

Minimalist designs that reduce material waste

Biodegradable outer packaging materials

Sustainable solutions can coexist with protective features, offering brands a way to align safety, quality, and environmental responsibility.

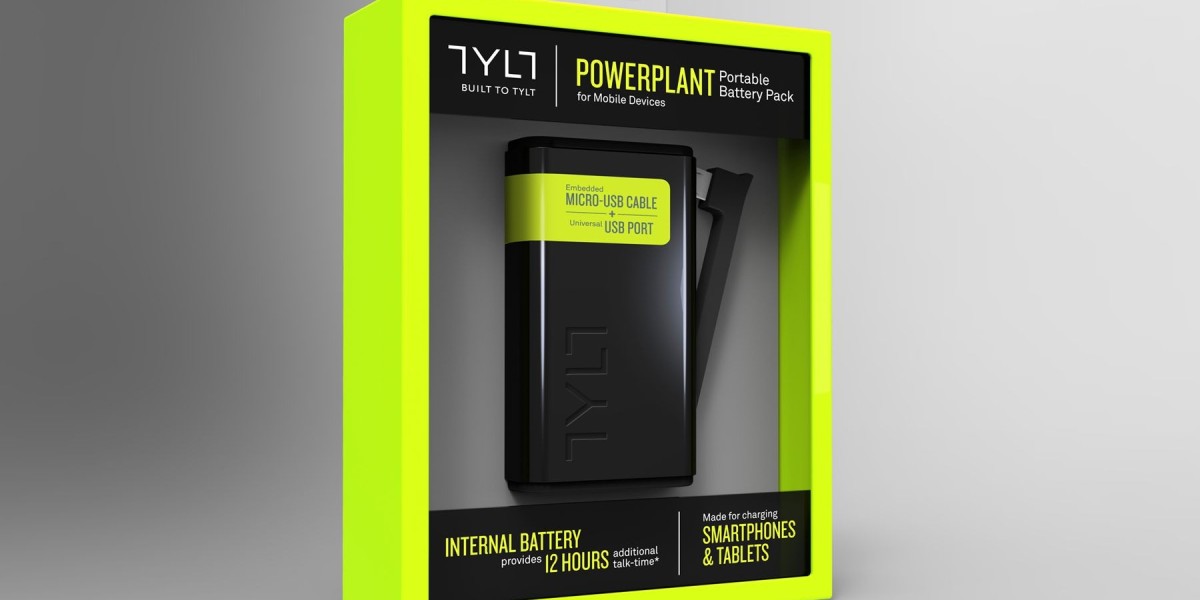

Enhancing Retail Appeal

Packaging is not only functional but also a critical marketing tool. Eye-catching designs help batteries stand out on retail shelves, while organized compartments and clear labeling improve customer experience. Battery packaging boxes that combine aesthetics with protection convey professionalism and brand reliability.

Streamlining Storage and Handling

Effective packaging also supports warehouse and retail operations. Features that improve storage and handling efficiency include:

Stackable boxes for optimized shelf space

Compartments that simplify inventory counts

Protective inserts that prevent product shifting during storage

Lightweight yet sturdy materials for easy handling

Streamlined handling reduces the likelihood of accidental damage and lowers operational costs.

Protecting Different Types of Batteries

Battery packaging must cater to various battery chemistries and sizes, including alkaline, lithium-ion, rechargeable, and specialty batteries. Each type has specific storage and transport requirements:

Lithium-ion batteries: require insulation and short-circuit protection

Alkaline batteries: need moisture-resistant packaging

Rechargeable packs: benefit from reinforced boxes and compartments

Customizable retail battery packaging solutions ensure that all battery types are properly secured, maintaining their performance and safety.

Reducing Returns and Customer Complaints

Damaged batteries not only pose safety risks but also result in increased returns and customer dissatisfaction. Protective packaging reduces:

Product returns due to leakage or breakage

Complaints related to short-circuiting or reduced lifespan

Operational losses from discarded or damaged stock

Investing in safety-compliant battery packaging is therefore a proactive approach to maintain profitability and brand reputation.

Conclusion: Investing in Reliable Battery Packaging

Proper packaging is a critical factor in the safety, performance, and consumer perception of batteries. A retail battery packaging solution safeguards products from environmental and mechanical hazards, preserves chemical integrity, supports regulatory compliance, and enhances retail appeal.

By combining protective, eco-friendly, and well-designed custom box packaging, manufacturers and retailers can ensure batteries reach end-users safely, maintain their functionality, and reinforce brand trust. High-quality packaging is not just a protective measure—it is a strategic investment in product longevity, operational efficiency, and customer satisfaction.