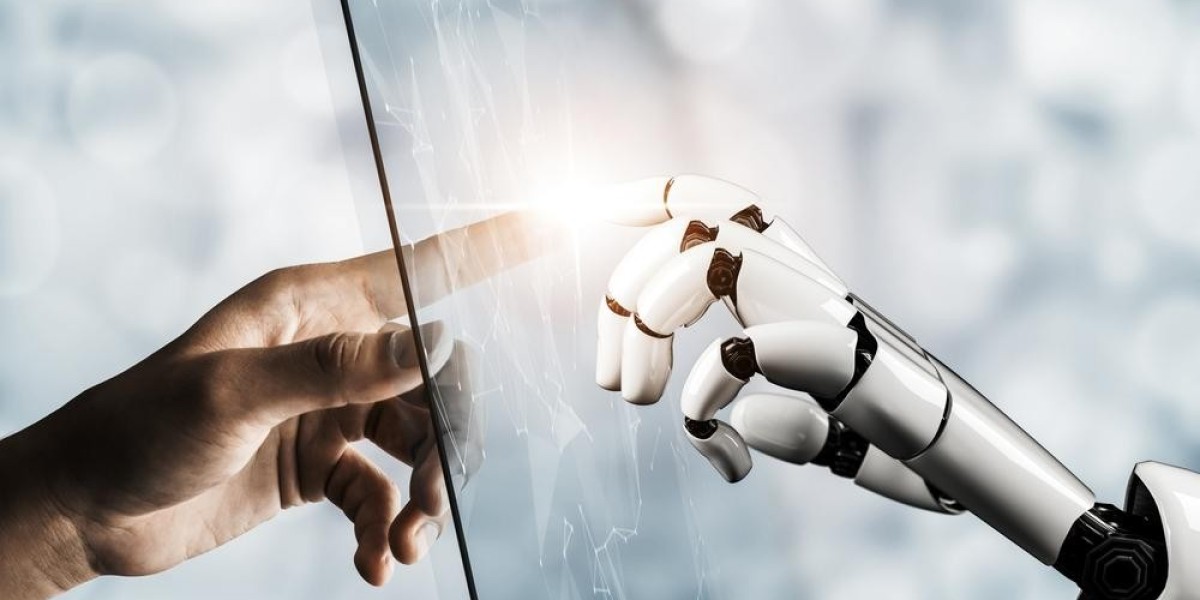

Automation Starts With Intelligent Interaction

Modern automation is no longer limited to simple repetitive actions. Today, machines must interact with physical objects in complex environments. They need to grasp, move, adjust, and release items with accuracy and care. This demand has driven innovation in robotic systems that can perform human like movements.

At the center of this transformation stands the Robotic Hand. It serves as the physical link between digital instructions and real world action. Through careful design and intelligent control, it allows machines to handle objects with speed, precision, and reliability. Without this capability, modern automation would remain incomplete.

Sensors Are the Eyes and Sense of Touch

Sensors form the foundation of robotic hand technology. They allow machines to understand their surroundings instead of blindly following commands. By collecting real time data, sensors guide every movement and decision made by the system.

These sensors monitor pressure, position, speed, and resistance. As a result, the robotic hand reacts dynamically to changes in its environment. This awareness makes automation safer, smarter, and more adaptable. It also reduces errors that could damage products or equipment.

Types of Sensors Used in Robotic Hands

Force and pressure sensors

Force and pressure sensors help the robotic hand understand how tightly it is gripping an object. This function is critical when handling delicate components such as electronics or glass. Too much force could cause damage, while too little could result in slippage.

These sensors continuously send feedback to the control system. The system then adjusts grip strength instantly. This ability ensures stable handling while maintaining safety and precision throughout the operation.

Position and motion sensors

Position sensors track the exact placement of fingers and joints. Motion sensors monitor speed and direction during movement. Together, they ensure that every action follows a precise path.

This information allows the robotic hand to repeat tasks with remarkable consistency. As a result, manufacturers can rely on uniform quality across large production volumes. Precision becomes predictable and scalable.

Actuators Turn Data Into Movement

While sensors gather information, actuators create movement. They act as the muscles of the robotic hand by converting electrical signals into mechanical motion. Each finger movement depends on actuator performance.

High quality actuators provide smooth and controlled motion. They reduce vibration and allow gradual adjustments. This smoothness improves handling accuracy and extends component lifespan. Reliable actuators also contribute to overall system efficiency and durability.

Control Systems That Coordinate Every Action

Central processing and decision making

The control system functions as the brain of the robotic hand. It processes sensor data and determines how the hand should respond. This decision making happens in milliseconds and ensures fluid operation.

The system compares real time input with programmed instructions. If conditions change, it adjusts movements immediately. This responsiveness allows the robotic hand to perform complex tasks without interruption.

Feedback loops for continuous accuracy

Feedback loops play a vital role in maintaining precision. Sensors report the outcome of each movement back to the control system. The system then refines future actions based on this feedback.

This continuous loop improves performance over time. Movements become more accurate and reliable. As a result, the robotic hand adapts to different tasks with minimal reprogramming.

Smart Control Through Software and Algorithms

Software defines how the robotic hand behaves. Algorithms interpret sensor data and decide movement patterns. Together, they enable intelligent control rather than rigid automation.

Advanced algorithms allow the robotic hand to adjust grip strength, speed, and motion based on task requirements. This adaptability supports a wide range of industrial applications. Machine learning further enhances performance by allowing systems to improve through experience.

Human Machine Collaboration Made Possible

Smart control allows humans and machines to work together effectively. Operators define goals and parameters. The robotic hand executes tasks with precision and consistency.

This collaboration reduces physical strain on workers. It also improves safety by handling hazardous or repetitive tasks. Over time, trust builds between human operators and automated systems, leading to smoother workflows.

Calibration Ensures Reliable Performance

Calibration aligns the robotic hand with specific task requirements. It establishes reference points and operating limits. Without proper calibration, even advanced systems can produce errors.

Regular calibration ensures consistent accuracy. It also compensates for wear and environmental changes. This process plays a critical role in long term reliability and performance stability.

Safety Built Into Smart Control Systems

Safety remains a priority in automation. Robotic hand control systems include safeguards such as force limits and emergency stops. These features protect workers and equipment.

Sensors detect unexpected resistance or obstacles. The system responds by slowing down or stopping movement. This proactive approach reduces accidents and allows safe collaboration between humans and machines.

Applications That Depend on Smart Control

Smart control enables robotic hands to perform in diverse environments. Manufacturing relies on precise assembly. Logistics depends on accurate sorting and packaging. Healthcare requires gentle and controlled handling.

The Robotic Hand adapts to each environment through software and sensor feedback. This versatility explains its growing role across industries. Smart control determines how effectively it performs.

Challenges and Ongoing Development

Despite progress, challenges remain. Complex systems require maintenance. Sensors and actuators experience wear over time. Software must be updated to stay effective.

Balancing speed with accuracy also presents difficulty. Faster movement can increase error risk. Engineers continue to refine designs to overcome these limitations and improve performance.

Data Driven Improvement and Learning

Data collected during operation supports continuous improvement. Performance metrics reveal inefficiencies and errors. Engineers use this information to refine algorithms and control strategies.

This data driven approach ensures steady innovation. Systems evolve based on real world usage rather than assumptions. Over time, automation becomes more intelligent and efficient.

The Future of Smart Robotic Control

Future developments will focus on deeper adaptability. Artificial intelligence will enable predictive movement and faster decision making. Control systems will become more autonomous.

Cloud integration will allow remote updates and monitoring. As a result, robotic hands will scale more easily across facilities. Smart control will define the next generation of automation.

Why Understanding Robotic Hand Technology Matters

Understanding how robotic hands work helps businesses make informed decisions. It clarifies what drives precision, safety, and efficiency.

Knowledge also supports better system integration. Organizations can align automation with long term goals. This understanding ensures lasting value from investment.

A Clear Picture of Intelligent Automation

Robotic hand technology combines sensing, actuation, and smart control into one system. Each element supports the others. Together, they enable intelligent interaction with the physical world.

The Robotic Hand represents the future of automation. It shows how thoughtful design and smart control turn machines into capable and reliable partners.