A fiber optic laser welder represents a modern welding solution designed to meet these demands across diverse industrial sectors. LaserChina has established itself as a trusted brand in advanced laser systems, delivering welding solutions that align with the evolving needs of metal fabrication, automotive production, electronics, and heavy industry. By combining engineering expertise with industry insight, LaserChina positions its fiber optic laser welder as a reliable choice for manufacturers seeking refined welding outcomes.

LaserChina’s Approach to Advanced Welding Solutions

LaserChina focuses on developing laser welding systems that integrate seamlessly into industrial workflows. A fiber optic laser welder from LaserChina is engineered with attention to process stability, energy control, and long-term operational reliability. The brand emphasizes manufacturing consistency, ensuring each system meets strict quality benchmarks before deployment. This approach allows businesses to maintain production accuracy while scaling operations without compromising weld integrity.

How a Fiber Optic Laser Welder Fits Modern Manufacturing

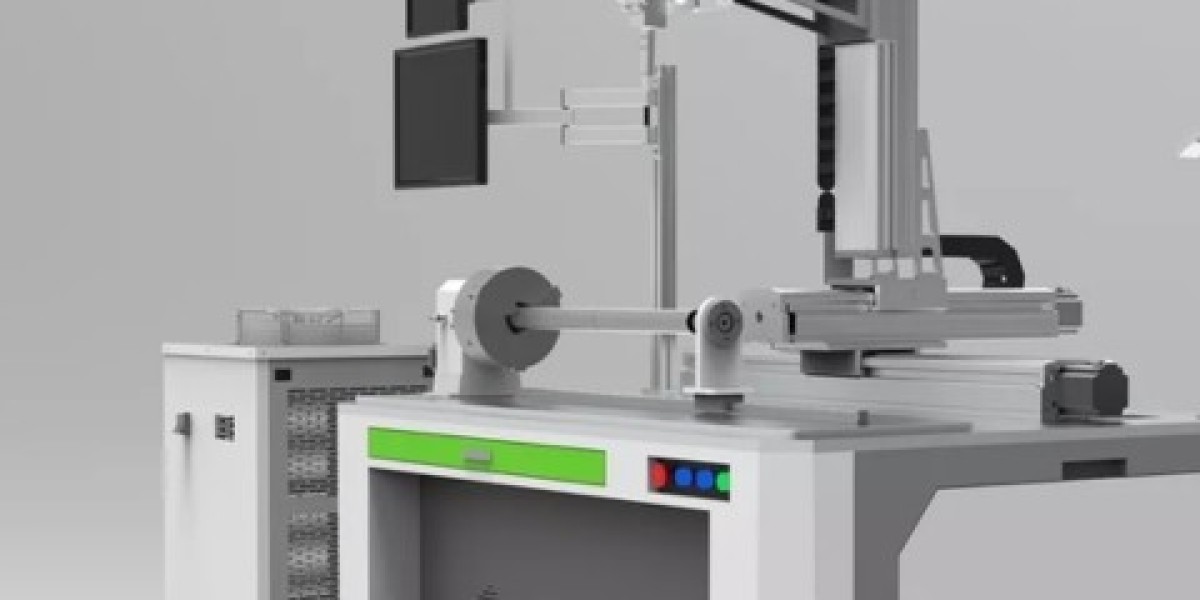

A fiber optic laser welder uses concentrated laser energy delivered through optical fiber to create controlled weld seams. This technology supports industries where precision and repeatability are essential. From thin metal components to complex assemblies, the welding process remains consistent, supporting high-volume production as well as specialized fabrication tasks. LaserChina designs its systems to adapt to different materials and thickness ranges, ensuring broad application across manufacturing sectors.

Industrial Applications Supported by LaserChina

LaserChina’s fiber optic laser welder is widely used in industries such as automotive manufacturing, aerospace fabrication, electronics assembly, medical device production, and general metalworking. In automotive production lines, it supports accurate joining of components while maintaining production speed. In electronics and medical manufacturing, where tolerance margins are minimal, LaserChina systems provide controlled welding results that align with strict industry standards. The adaptability of these systems makes them suitable for both automated lines and standalone workstations.

Precision and Process Control in Welding Operations

Process control is a critical factor in industrial welding. LaserChina integrates advanced control systems into its fiber optic laser welder solutions to ensure stable operation throughout production cycles. Operators benefit from predictable welding behavior, allowing them to maintain consistent output even during extended shifts. This level of control supports quality assurance objectives and reduces variability in finished products, which is vital for industries with compliance requirements.

Productivity and Operational Efficiency

Manufacturers adopting a fiber optic laser welder from LaserChina often focus on optimizing workflow efficiency. These systems are designed to support continuous operation while maintaining consistent welding performance. The streamlined integration into production environments allows manufacturers to align welding operations with broader manufacturing goals. LaserChina emphasizes system reliability, helping businesses maintain steady output without frequent interruptions.

Long-Term Value for Industrial Businesses

Investing in a fiber optic laser welder is a strategic decision for manufacturers focused on long-term growth. LaserChina’s systems are developed with durability and scalability in mind, enabling businesses to expand production capabilities as demand increases. By aligning system design with industrial requirements, LaserChina ensures its welding solutions remain relevant as manufacturing technologies evolve.

Why Manufacturers Trust LaserChina

LaserChina has earned industry trust through consistent performance, engineering expertise, and customer-focused development. Each fiber optic laser welder reflects the brand’s commitment to supporting industrial productivity and precision. Manufacturers value LaserChina not only for its equipment quality but also for its understanding of real-world production challenges. This alignment between technology and application strengthens LaserChina’s position in the global laser welding market.

Final Thoughts

A fiber optic laser welder from LaserChina represents a refined welding solution for industries that prioritize precision, consistency, and operational stability. By focusing on quality engineering and industrial applicability, LaserChina delivers systems that support modern manufacturing demands. Businesses seeking dependable laser welding technology can rely on LaserChina to provide solutions aligned with current and future production needs.