Understanding the cost is not just about the number you see on a quotation. It is about knowing what contributes to the final figure, why different models vary in price, and how these machines fit into different types of work environments. In this guide, we will take a close look at what determines the laser cleaner price, the range you might expect, and why businesses see it as a long-term investment.

Why Laser Cleaner Price Varies Across Models

The laser cleaner price is never a single fixed value because manufacturers design machines to meet different performance levels and industrial demands. For instance, a compact portable unit designed for light cleaning jobs will naturally have a different price compared to a large industrial-grade system meant for continuous operation in factories.

Key aspects that influence the price include:

Power capacity of the laser source, usually measured in watts. Higher power means faster cleaning and a higher price.

Technology build, such as whether the unit uses pulsed or continuous fiber lasers.

Cooling mechanism, where advanced cooling systems support longer operating hours and raise the overall price.

Automation level, because machines with robotic arms or integration capability for automated production lines demand more investment.

Brand reputation, since established manufacturers with global service networks often charge more for reliability, warranties, and after-sales support.

These factors explain why some entry-level portable units may start at a relatively low figure while industrial-grade cleaners can reach a much higher price bracket.

Typical Laser Cleaner Price Range

For professionals exploring the market, knowing the laser cleaner price range is essential to budgeting. While prices shift depending on specifications and region, here is a realistic breakdown based on machine categories:

Portable handheld laser cleaners (100W – 200W): These are generally the entry-level machines, designed for smaller workshops, repair centers, and light-duty industrial use. The price may begin from around $7,000 to $15,000.

Mid-range industrial units (300W – 1000W): These are suited for factories or businesses that need faster cleaning speeds and the ability to handle thicker layers of rust, paint, or coatings. Their price often falls between $20,000 and $60,000.

High-power laser cleaners (1500W and above): Designed for heavy-duty and continuous industrial operations such as shipyards, aerospace, or large-scale metal treatment plants, these systems can range from $70,000 to over $200,000.

This wide range highlights why it is important to match the machine type with the specific job requirements.

Understanding What You Pay for Beyond the Laser Cleaner Price

When evaluating a purchase, many buyers look at the laser cleaner price alone. However, cost goes beyond the purchase invoice. Buyers must also consider:

Training and installation – Some manufacturers include operator training, while others charge separately.

Maintenance costs – Although laser cleaners generally require less upkeep compared to chemical-based methods, preventive maintenance is still essential.

Replacement parts – Components like protective lenses and filters may require periodic replacement.

Warranty and service agreements – Higher-priced machines from well-known brands often include more comprehensive warranties, reducing long-term risk.

All of these elements add to the real cost of ownership. A slightly higher upfront laser cleaner price may prove more economical in the long run if it ensures reliability and fewer disruptions.

Industries Where Laser Cleaner Price Justifies the Investment

The demand for laser cleaning spans across many industries. What makes the laser cleaner price acceptable for these industries is not only the ability to clean surfaces but also the savings in time, efficiency, and reduced use of consumables.

Automotive workshops use handheld laser cleaners to remove rust from vehicle components, improving restoration quality.

Manufacturing plants rely on mid-range systems for cleaning molds, machine parts, and welded surfaces without damaging the material.

Aerospace companies invest in high-power machines because precise and non-contact cleaning is essential for safety standards.

Shipbuilding and marine industries use industrial-grade cleaners to deal with large-scale corrosion and coating removal.

Electronics manufacturers apply laser cleaning in micro-level operations where chemical cleaning would be too aggressive.

In each case, the laser cleaner price pays back in terms of reduced labor, faster turnaround times, and consistency in results.

Factors to Consider Before Choosing a Laser Cleaner

Before finalizing a purchase, it is important to evaluate more than just the laser cleaner price. Businesses should clearly define:

Type of material and contaminants they need to clean.

Volume of work—whether occasional cleaning or continuous operation is required.

Available workspace and portability requirements.

Budget allocation not just for the machine but also for installation and maintenance.

By matching these factors with the right machine, buyers can ensure that the chosen system aligns with their operational needs and financial capacity.

Global Market Trends and Price Shifts

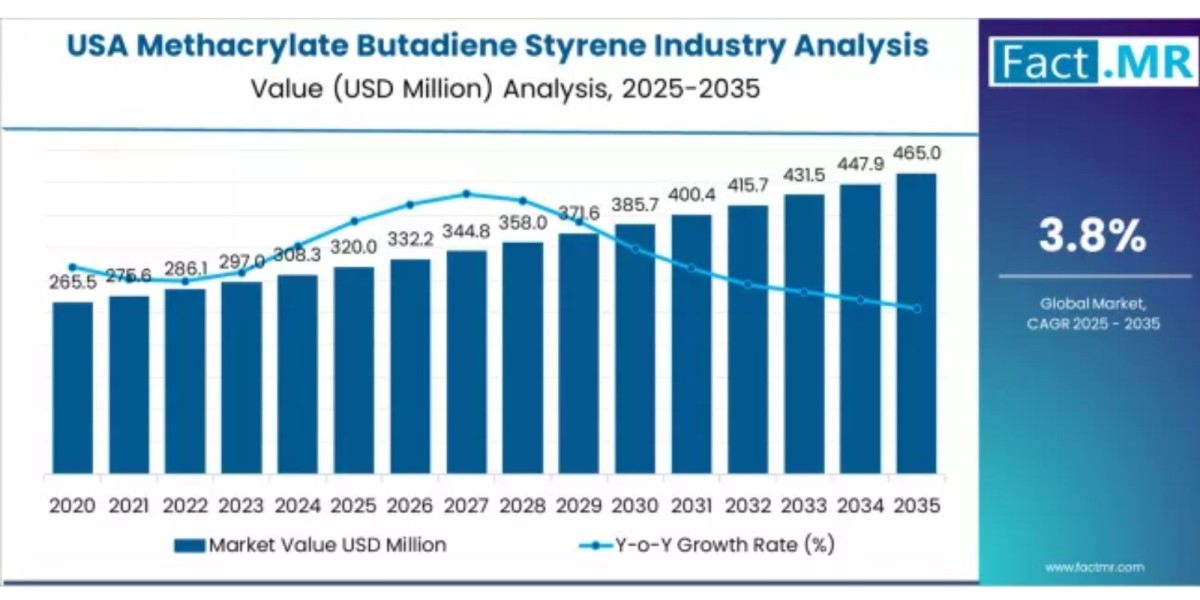

The global demand for laser cleaning machines has steadily grown, and this affects the laser cleaner price. With more manufacturers entering the market, competition has expanded, giving buyers more options in terms of cost. At the same time, innovations in fiber laser technology are driving down prices of entry-level models while enhancing performance.

For buyers, this means that the market is dynamic. Those who monitor industry trends often find opportunities to acquire machines at better prices, especially when manufacturers launch updated models or expand into new regions.

Promotional Consideration for Buyers

For businesses planning to integrate laser cleaning, understanding the laser cleaner price is only the first step. Selecting a reliable supplier who offers not just the machine but also training, after-sales service, and long-term support makes a significant difference.

Promotional offers, trade shows, and regional distributors often provide competitive pricing and financing solutions. Companies looking to upgrade from traditional cleaning methods should engage directly with suppliers to negotiate packages that suit their needs.

Final Thoughts

The laser cleaner price is not a one-size-fits-all figure. It depends on power levels, machine design, brand value, and the intended application. From portable units for workshops to industrial systems designed for heavy-duty operations, the range is broad, and buyers should carefully evaluate their requirements before making a decision. While the initial investment may appear significant, the long-term benefits in efficiency, precision, and reduced operational costs explain why industries around the world continue to adopt this technology.