In today’s fast-paced manufacturing environment, precision and speed are everything. Whether you're producing automotive parts, aerospace components, or complex electronic assemblies, maintaining consistent quality while keeping up with demand can be a challenge. That’s where assembly fixtures come in. These essential tools help streamline production, reduce human error, and ensure that every product meets exact specifications.

Assembly Fixtures act as the foundation for accurate part positioning, secure workholding, and repeatable manufacturing processes. They help teams eliminate guesswork and achieve reliable, high-quality results. To explore professional fixture solutions tailored for modern production, you can visit Assembly Fixtures.

In this article, we’ll break down how assembly fixtures improve accuracy and efficiency, the different types available, and why they are indispensable in high-performance manufacturing.

What Are Assembly Fixtures?

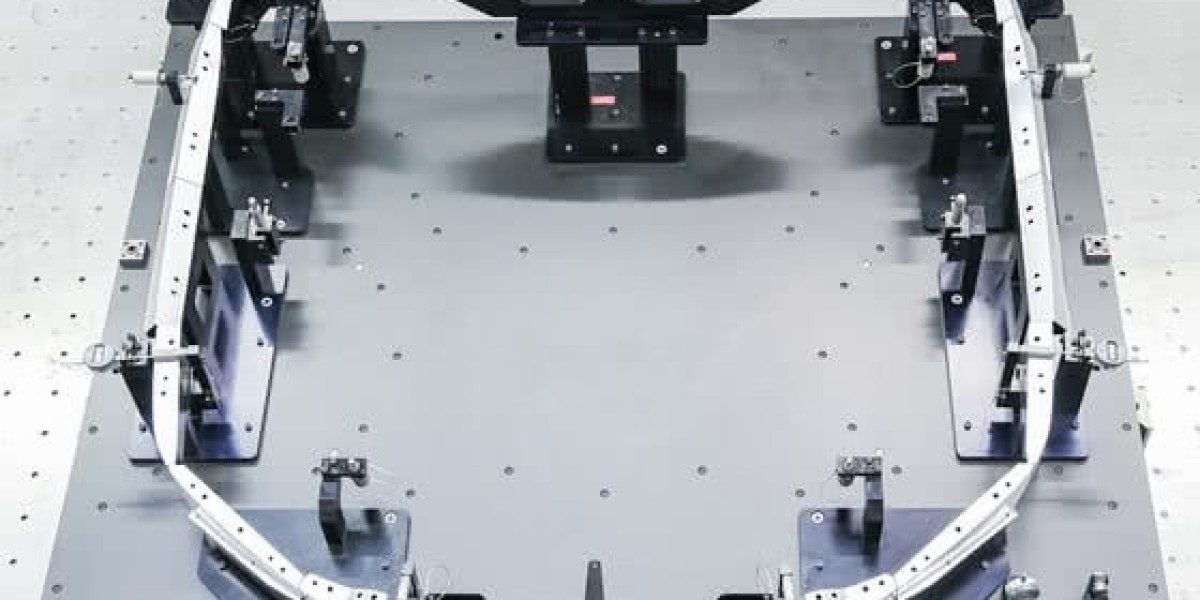

Assembly fixtures are specially designed tools used to hold, support, and position components during the production or assembly process. They ensure that each part is placed in the correct orientation, making it easier—and more reliable—for workers or automated systems to assemble the product.

Fixtures are commonly used across various industries including automotive, electronics, aerospace, and heavy machinery manufacturing.

Why Assembly Fixtures Matter in Modern Manufacturing

Manufacturing today demands precision, repeatability, and speed. Assembly fixtures help meet those requirements by:

Reducing human error

Increasing assembly speed

Ensuring repeatable accuracy

Supporting automation systems

Improving operator safety

Enhancing overall product quality

Businesses that invest in high-quality fixtures often see significant improvements in workflow and reduced rework or scrap rates. Many companies rely on advanced Assembly Fixtures solutions to optimise performance and consistency across their production lines.

1. Improved Production Accuracy

Accuracy is one of the biggest benefits of using assembly fixtures.

Why Fixtures Boost Accuracy

Fixtures ensure parts are held in the exact same position every single time. This eliminates alignment errors and prevents inconsistencies that could affect product quality.

Where This Matters Most

Precision drilling

Welding and soldering

Component alignment

Robotic assembly

When accuracy is consistent, production quality increases significantly and defects become far less common.

2. Enhanced Repeatability

Repeatability is essential for high-volume manufacturing. Every finished product must meet identical specifications.

How Fixtures Improve Repeatability

With fixtures, assembly tasks don’t rely on operator judgment. Instead, the fixture dictates the exact placement and orientation of parts, ensuring reliable and repeatable results with each cycle.

Industry Examples

Automotive door panel assembly

Electronic board component installation

Aerospace structure fastening

Repeatability leads to fewer production errors and increased customer satisfaction.

3. Faster Assembly Processes

Time is money in manufacturing. Fixtures help reduce assembly time by guiding operators or robots through the correct sequence of movements.

Why Speed Improves With Fixtures

Components stay securely in place

Operators waste less time adjusting or realigning parts

Automated systems can work faster and more confidently

Use Cases

Snap-fit assembly

Fastening and tightening

Precision part insertion

Faster cycle times increase overall productivity, allowing manufacturers to meet tight deadlines and high demand.

4. Reduced Operator Fatigue and Training Time

Fixtures simplify complex tasks, making them easier and less tiring for human operators.

Benefits for Workers

Less manual effort required

Ergonomic positioning reduces strain

Tasks become more intuitive

This also means new operators can be trained more quickly because the fixture guides them through the correct assembly process.

Outcome

Consistent performance—even from less experienced workers—and reduced risk of injury.

5. Increased Safety on the Production Floor

Safety is a top priority in any factory. Assembly fixtures help create a safer work environment by minimising manual handling and stabilising parts.

Safety Improvements Include

Secure clamping reduces part movement

Fixtures support heavy components

Less physical strain on workers

Reduced risk of dropped or mishandled parts

Automation-ready fixtures also reduce the need for direct human interaction during dangerous or repetitive tasks.

6. Compatibility With Automated Systems

Automation is transforming manufacturing, and fixtures are essential in enabling that transition.

How Fixtures Support Automation

Provide reliable reference points for robotic arms

Ensure consistent placement for vision systems

Improve precision for automated fastening and welding

Robots need predictable environments. Fixtures provide that stability.

In some industries, integrated fixture solutions allow companies to scale their automation capabilities rapidly. Businesses investing in automated equipment often start with robust fixture systems to guarantee long-term success.

7. Reduction in Scrap and Rework

Every manufacturer wants to reduce waste. Fixtures help ensure parts are assembled correctly the first time.

Why Scrap Is Reduced

Better accuracy = fewer mistakes

Consistent alignment reduces misfits

Operators are less likely to damage parts

Rework and scrap costs can add up quickly. Using assembly fixtures often leads to measurable savings across the production line.

8. Streamlined Quality Control

Some fixtures are specifically designed with quality control in mind.

QC Fixture Benefits

Measure dimensions quickly and accurately

Validate part alignment

Check component fit and tolerance

This allows teams to verify product quality at multiple points throughout the assembly process, preventing defects from reaching final inspection.

9. Customisation for Specialised Production Needs

One of the best things about fixtures is that they can be customised for specific parts and processes.

Custom Fixtures Offer

Exact fit for unique components

Enhanced precision for complex assemblies

Optimised workflow tailored to production needs

Industries with complex components—such as aerospace and defence—often rely on custom fixtures to ensure they meet strict regulatory standards.

10. Cost Savings Over Time

Although fixtures require an initial investment, the long-term cost savings are substantial.

Long-Term Benefits

Lower labour costs

Reduced scrap and rework

Faster cycle times

Improved product consistency

When you factor in these benefits, assembly fixtures quickly pay for themselves.

Many organisations turn to advanced manufacturing partners to design durable, high-performance fixtures that reduce costs while increasing output. Their engineering expertise ensures you get a solution built for your exact needs.

11. Improved Workflow Organisation

Fixtures help organise the assembly process by creating structured, repeatable workflows.

How This Helps

Less confusion among operators

Clear sequencing of tasks

Improved communication between workstations

A more organised workflow leads to smoother production and fewer delays.

12. Better Use of Skilled Labour

Fixtures allow skilled workers to focus on tasks that truly require expertise.

How Fixtures Support Skilled Teams

They handle repetitive positioning tasks

Skilled operators can oversee multiple stations

Workers spend time on value-added tasks

This maximises efficiency and improves job satisfaction across the team.

Conclusion

Assembly fixtures are one of the most valuable tools in modern manufacturing. They improve accuracy, boost efficiency, enhance safety, and support automation across countless industries. Whether you're assembling small electronics or large automotive components, the right fixtures create a stable, repeatable, and high-quality production environment.